Inpage Navigation Section: Overview

Pushing engineering and performance boundaries is one of the few motorcycles that truly deserve to be called Instant Icons. Created without compromise and benefiting from the collective strength of Kawasaki Heavy Industries, the Ninja H2R demands respect and attracts the most skilled and committed riders. The H2R features: Ohlins rear suspension, up and down quick-shifter, aerodynamic devices, cornering management and a bank angle display. Ninja H2R, play your part in history. This vehicle is not manufactured for public road use.

Colour

Inpage Navigation Section: Gallery

Inpage Navigation Section: Features & Specs

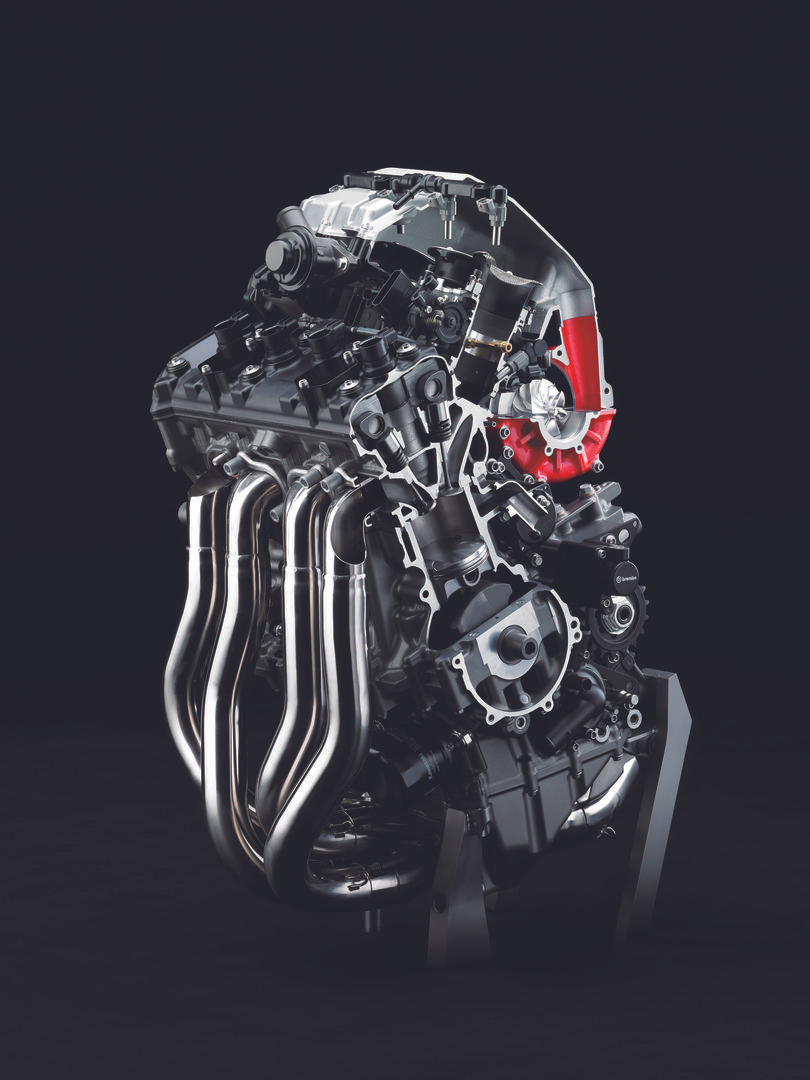

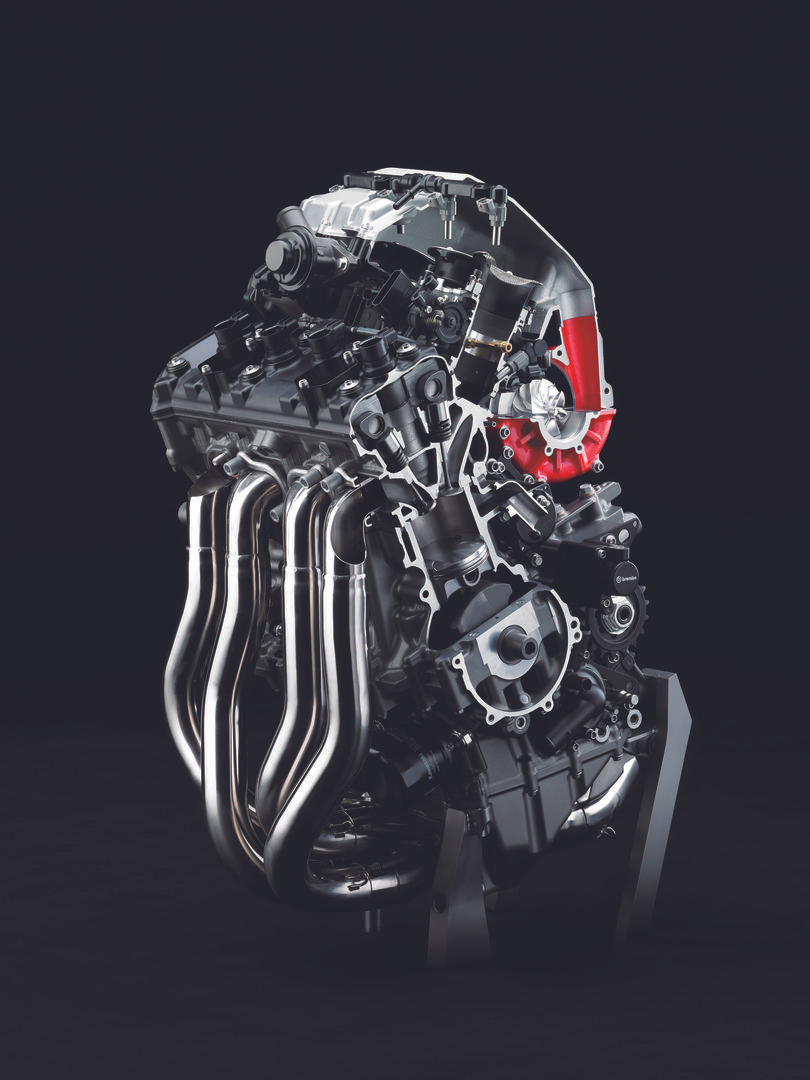

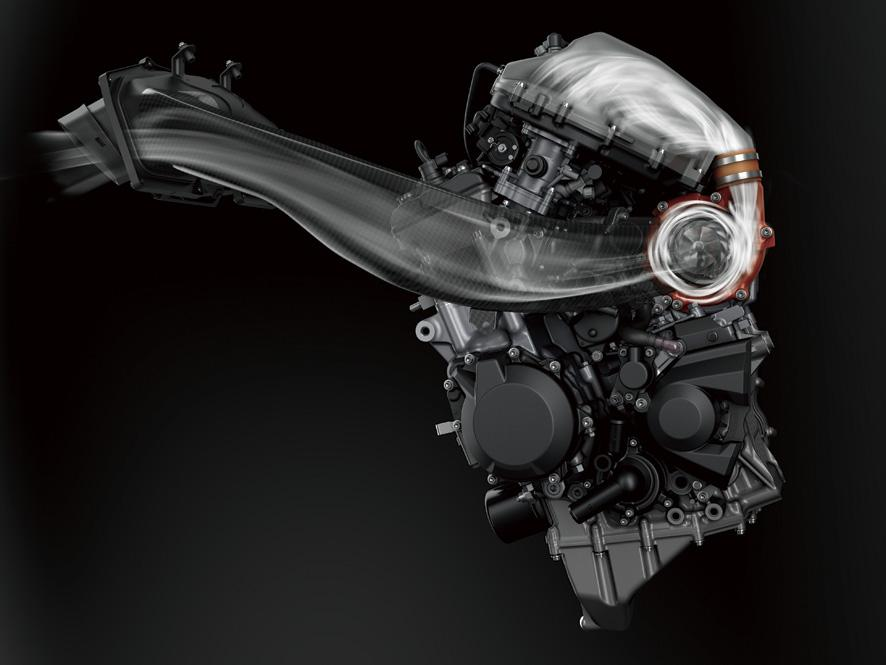

The supercharger used in the Ninja H2R was designed by Kawasaki motorcycle engine designers with assistance from other companies within the KHI Group, namely the Gas Turbine & Machinery Company, Aerospace Company, and Corporate Technology Division.

The supercharger used in the Ninja H2R was designed by Kawasaki motorcycle engine designers with assistance from other companies within the KHI Group, namely the Gas Turbine & Machinery Company, Aerospace Company, and Corporate Technology Division.

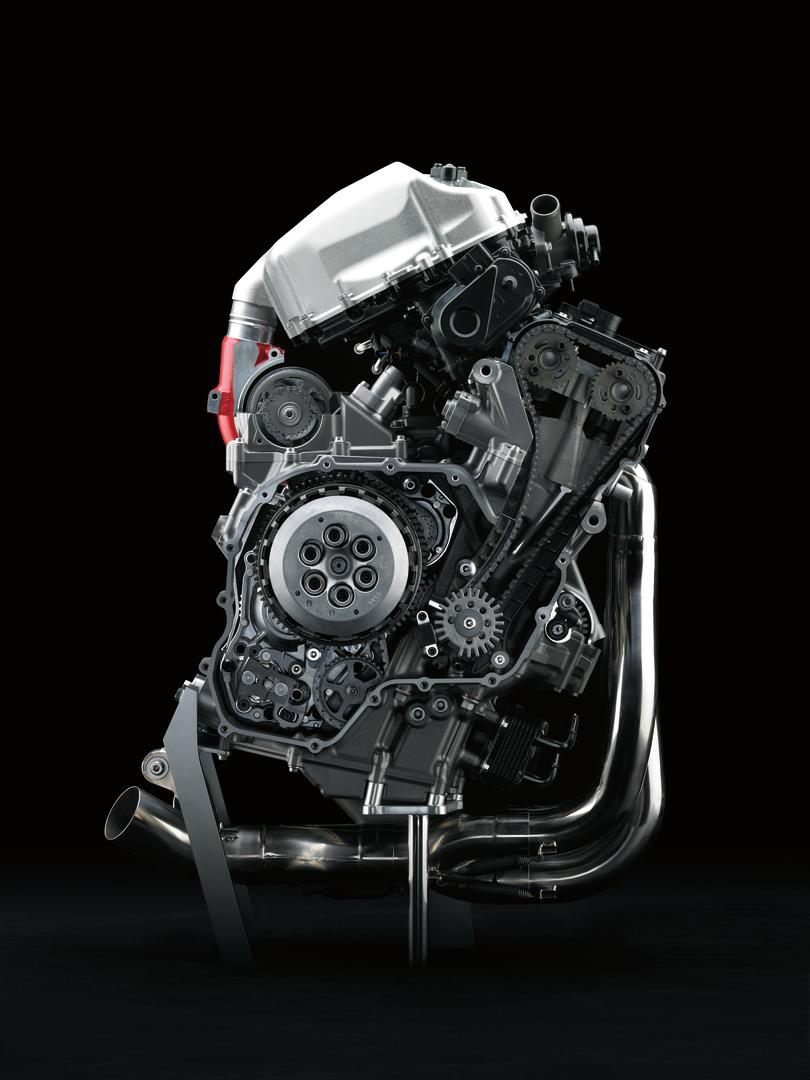

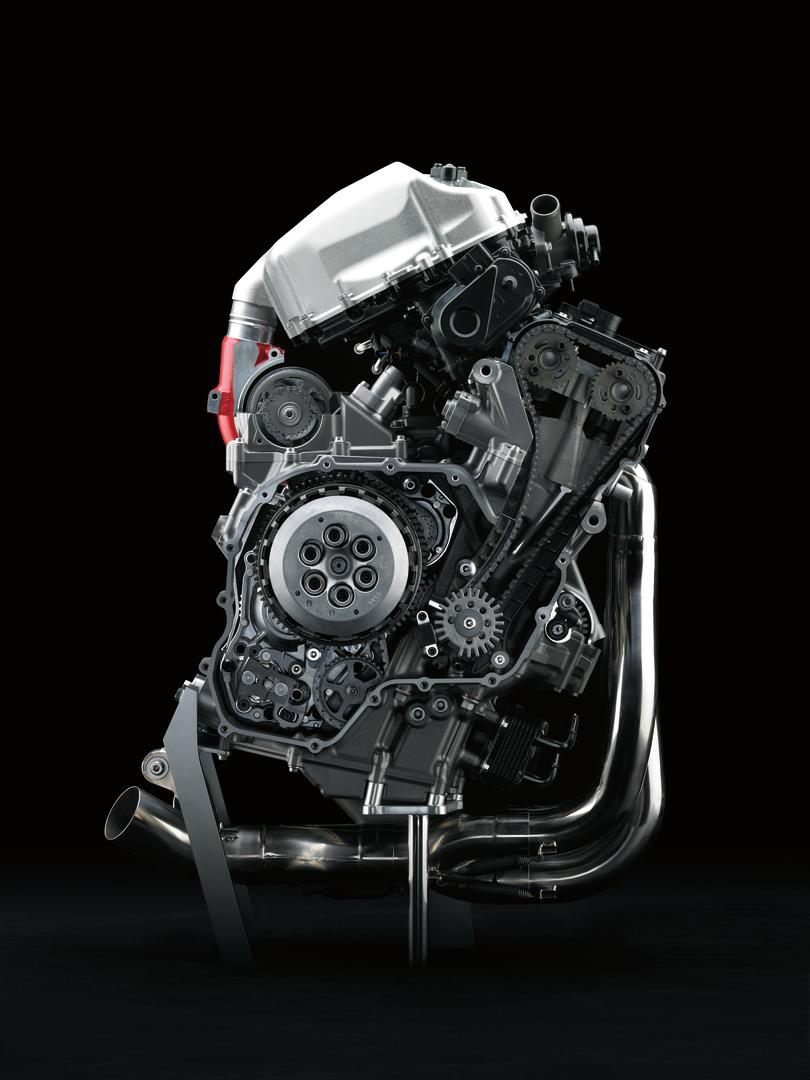

Despite it’s familiar In-Line Four configuration, the Ninja H2R power unit is loaded with technology developed specifically for this supercharged engine: some new, others with know-how from the Kawasaki Group.

Despite it’s familiar In-Line Four configuration, the Ninja H2R power unit is loaded with technology developed specifically for this supercharged engine: some new, others with know-how from the Kawasaki Group.

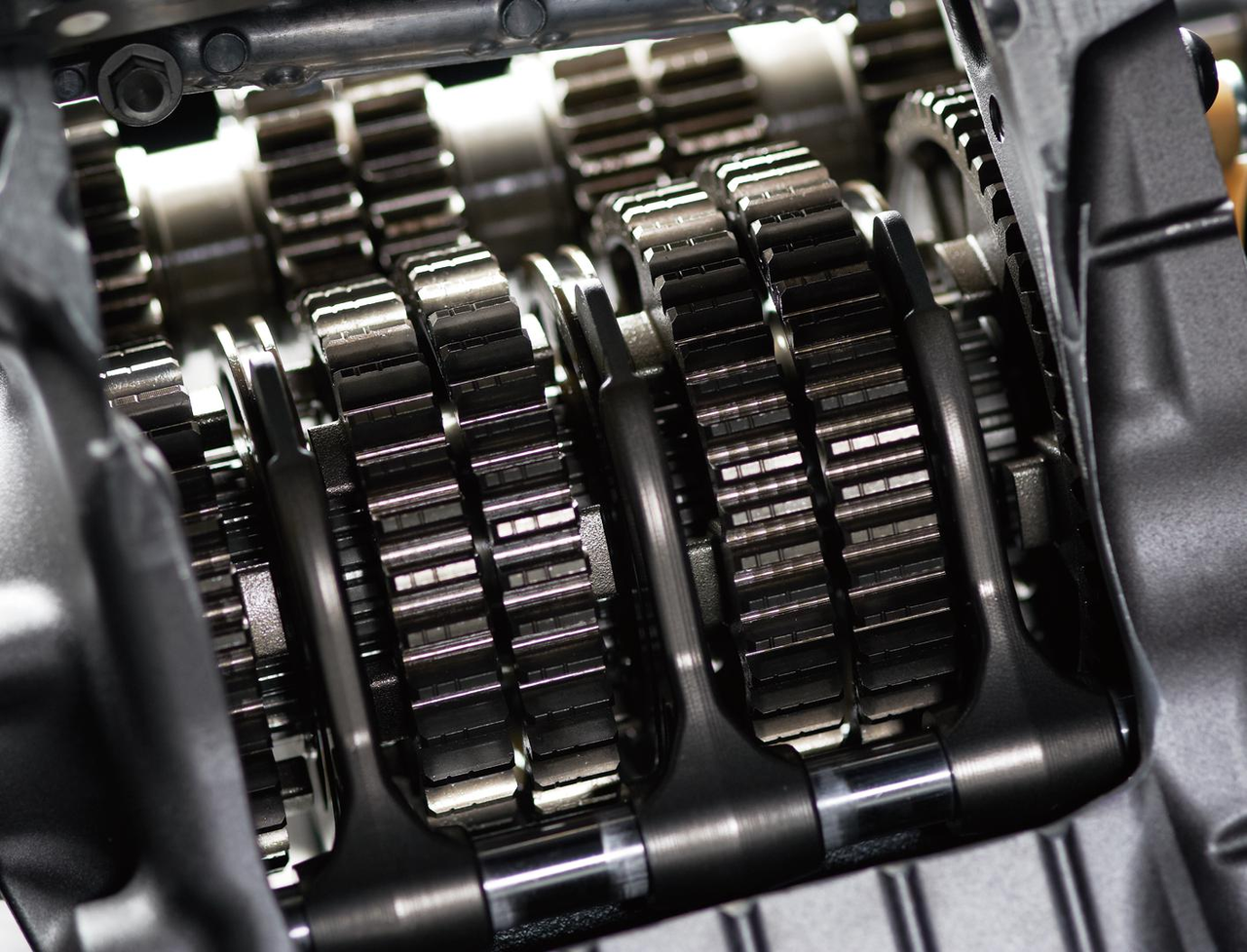

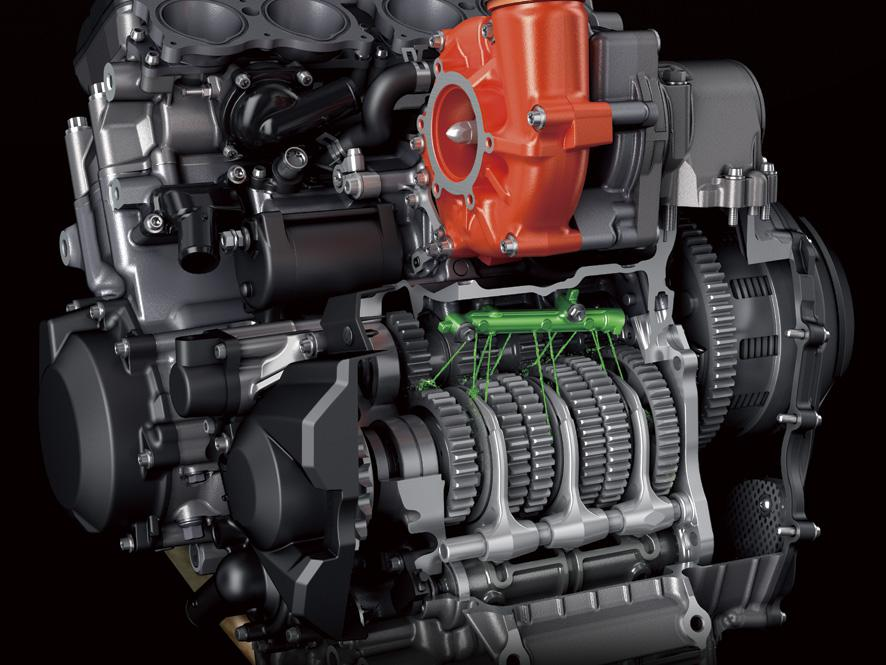

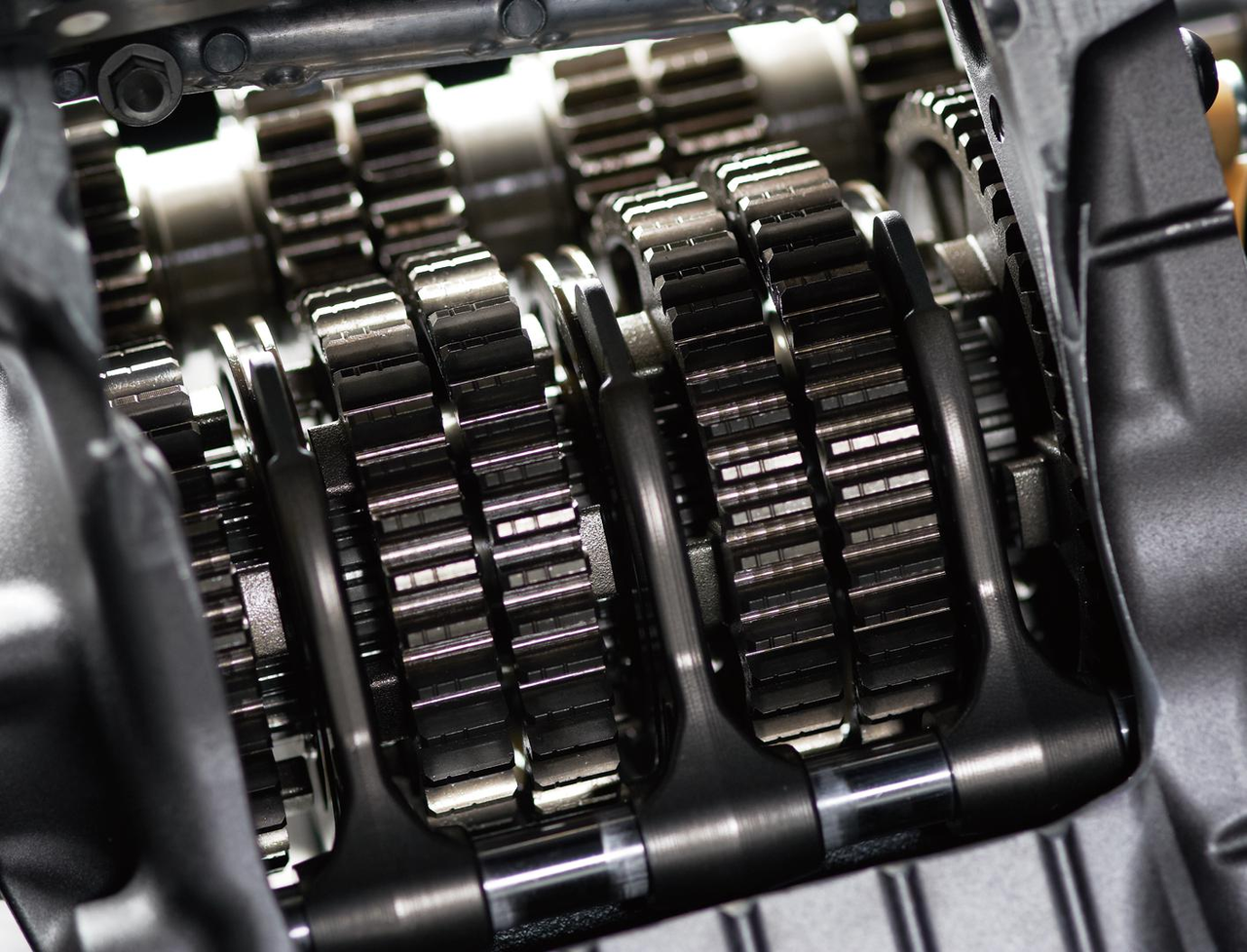

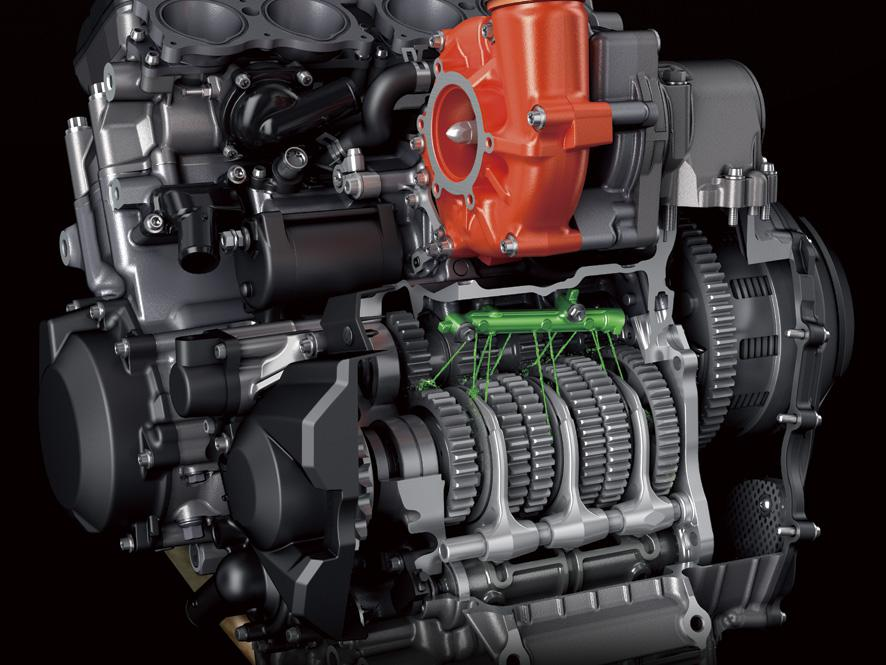

To facilitate smooth, quick shifting, a dog-ring type transmission was selected. This is the kind of transmission commonly found in MotoGP or Formula 1, and was developed with feedback from the Kawasaki Racing Team.

To facilitate smooth, quick shifting, a dog-ring type transmission was selected. This is the kind of transmission commonly found in MotoGP or Formula 1, and was developed with feedback from the Kawasaki Racing Team.

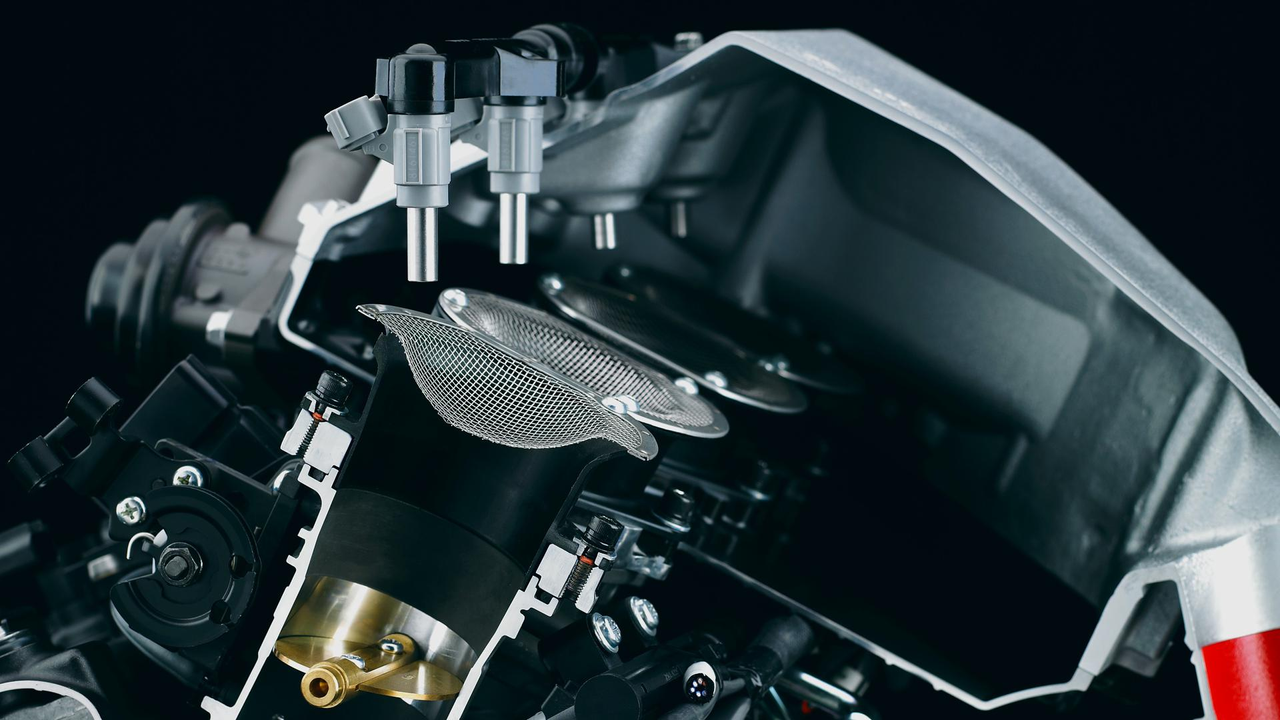

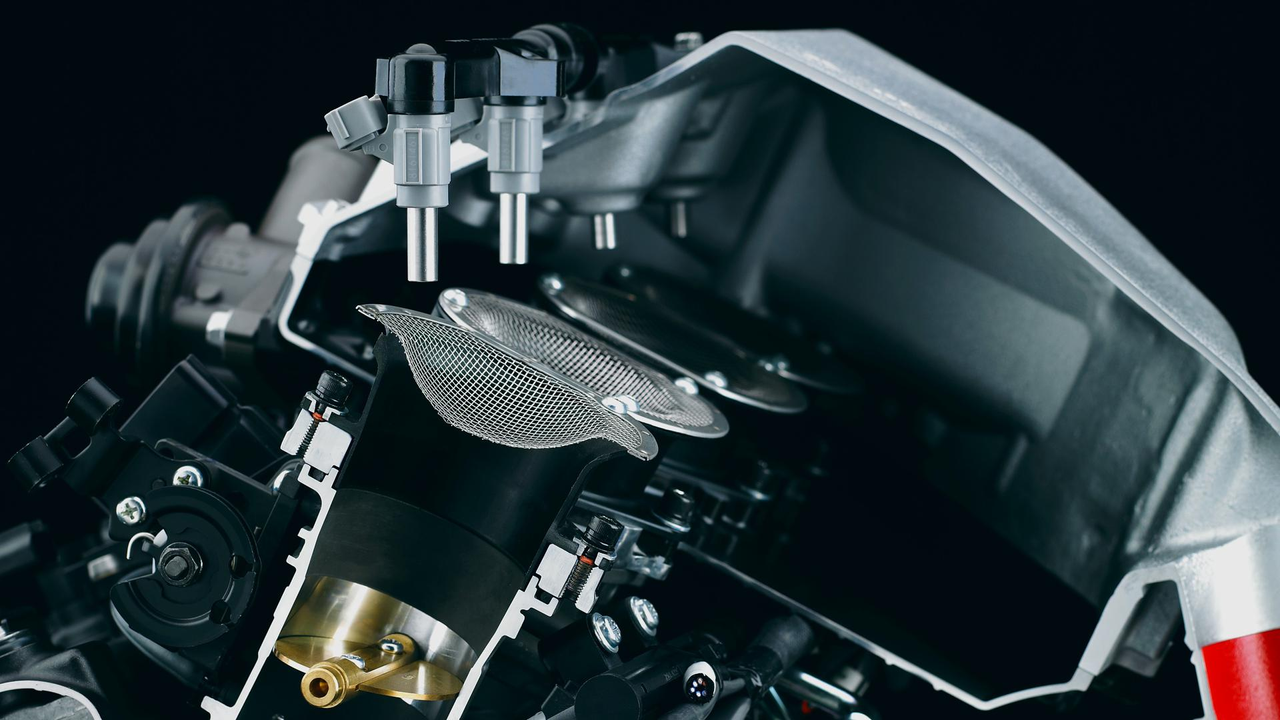

Kawasaki’s fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions

Kawasaki’s fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions

It is no accident that when viewed from the side, the Ninja H2R does not seem to have the aggressive forward-canted stance of most modern supersport models.

It is no accident that when viewed from the side, the Ninja H2R does not seem to have the aggressive forward-canted stance of most modern supersport models.

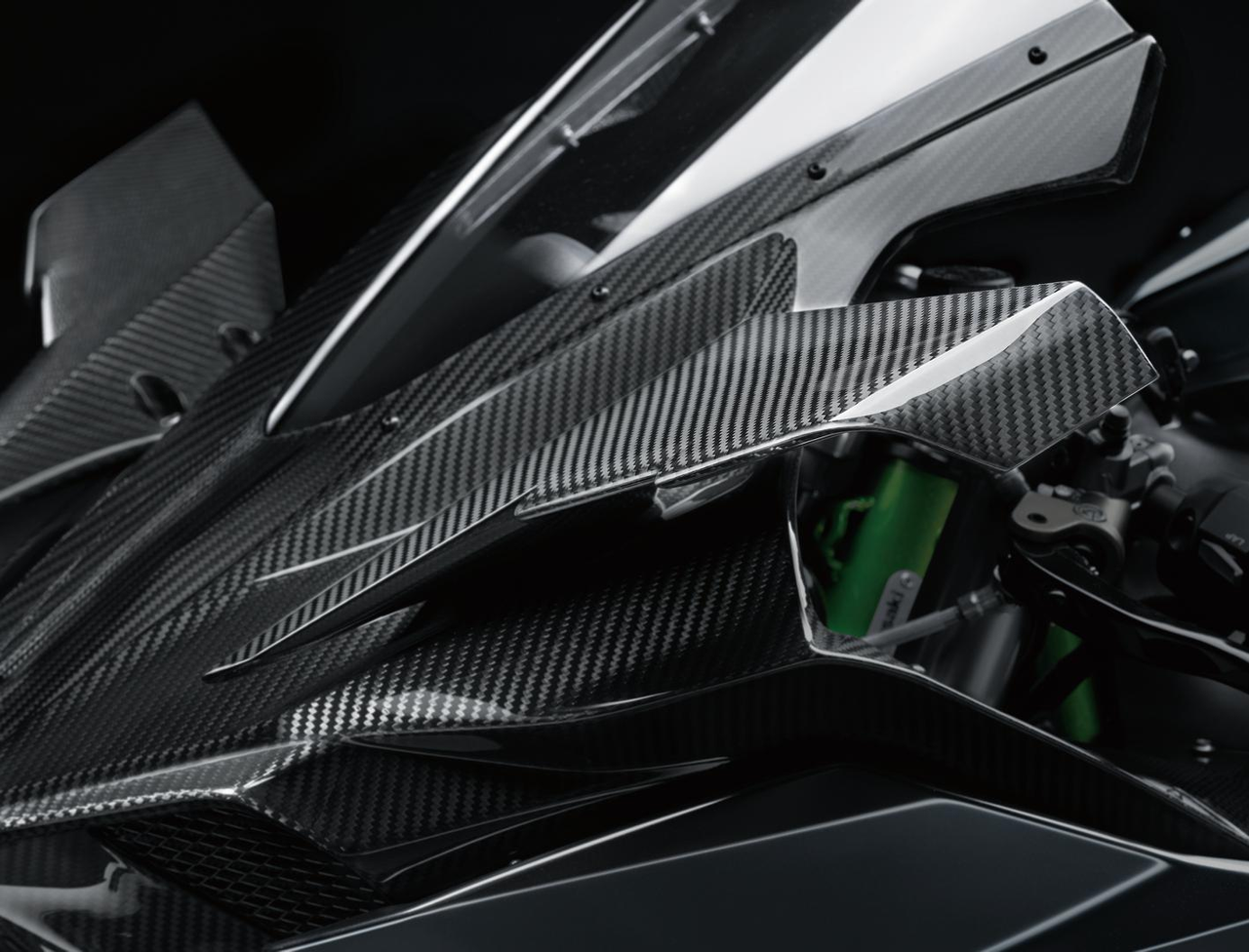

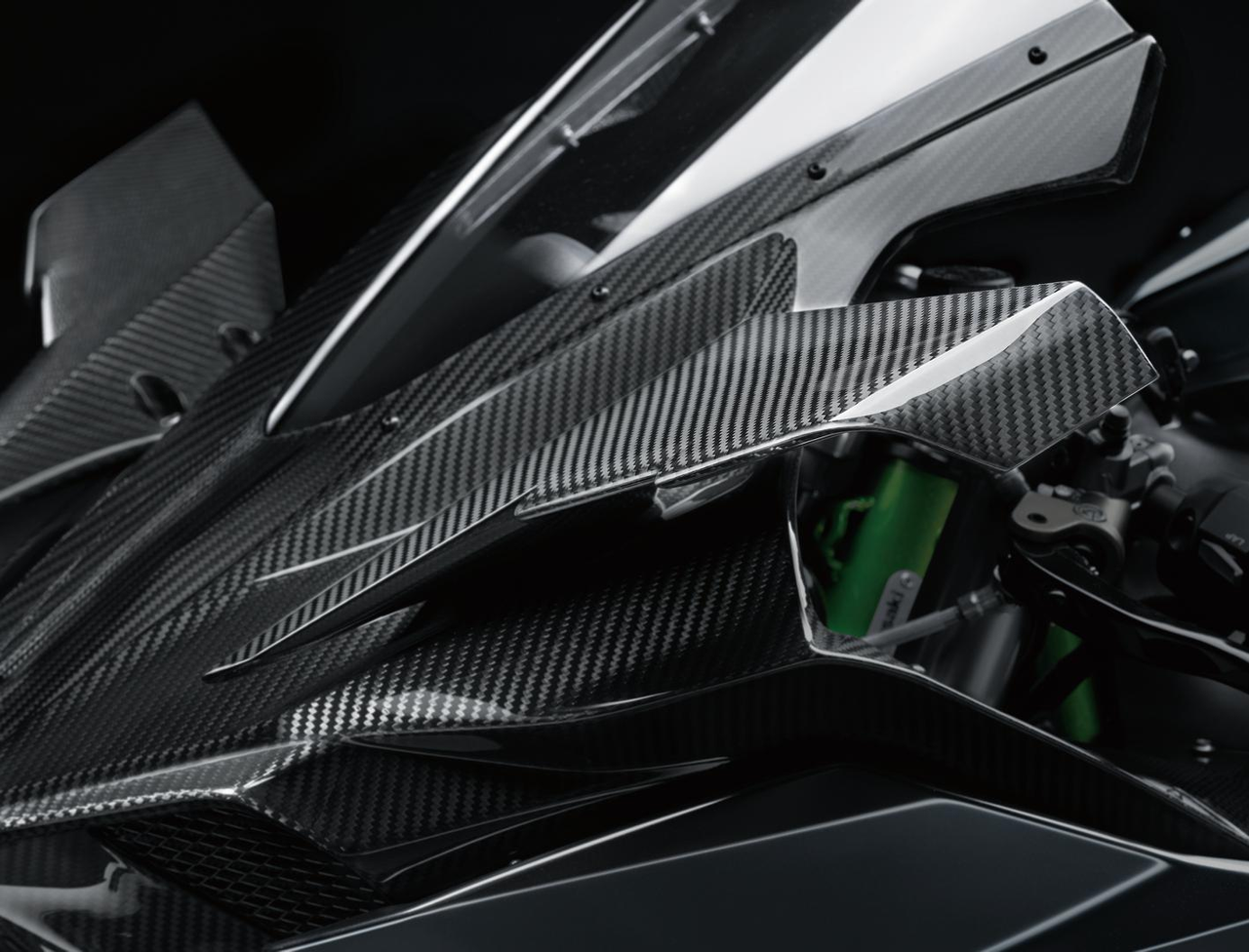

In place of mirrors, the Ninja H2R features CFRP wings mounted on the upper cowl.

In place of mirrors, the Ninja H2R features CFRP wings mounted on the upper cowl.

Full titanium exhaust system has a very simple design consisting of the header and collector pipes, a joint pipe, and a straightpipe megaphone-style silencer.

Full titanium exhaust system has a very simple design consisting of the header and collector pipes, a joint pipe, and a straightpipe megaphone-style silencer.

Having a single-sided swingarm allows the exhaust silencer to be mounted closer to the bike centreline, ensuring a high bank angle for sporty cornering.

Having a single-sided swingarm allows the exhaust silencer to be mounted closer to the bike centreline, ensuring a high bank angle for sporty cornering.

Kawasaki’s new Highly Durable paint features a special coat that allows scratches to repair themselves, enabling the paint to maintain its high-quality finish†. * Soft and hard segments in the coat work together like a chemical spring, creating a trampoline effect that absorbs impacts. † Notes: 1. In some cases, it takes about one week for recovery. 2. The paint will not recover in the case of scratches caused by a coin or key, or zip fasteners.

Kawasaki’s new Highly Durable paint features a special coat that allows scratches to repair themselves, enabling the paint to maintain its high-quality finish†. * Soft and hard segments in the coat work together like a chemical spring, creating a trampoline effect that absorbs impacts. † Notes: 1. In some cases, it takes about one week for recovery. 2. The paint will not recover in the case of scratches caused by a coin or key, or zip fasteners.

A high-quality hydraulic clutch offers less maintenance, ensuring the initial touch condition can be maintained. And with Brembo components, superb linearity and smooth actuation are also benefits.

A high-quality hydraulic clutch offers less maintenance, ensuring the initial touch condition can be maintained. And with Brembo components, superb linearity and smooth actuation are also benefits.

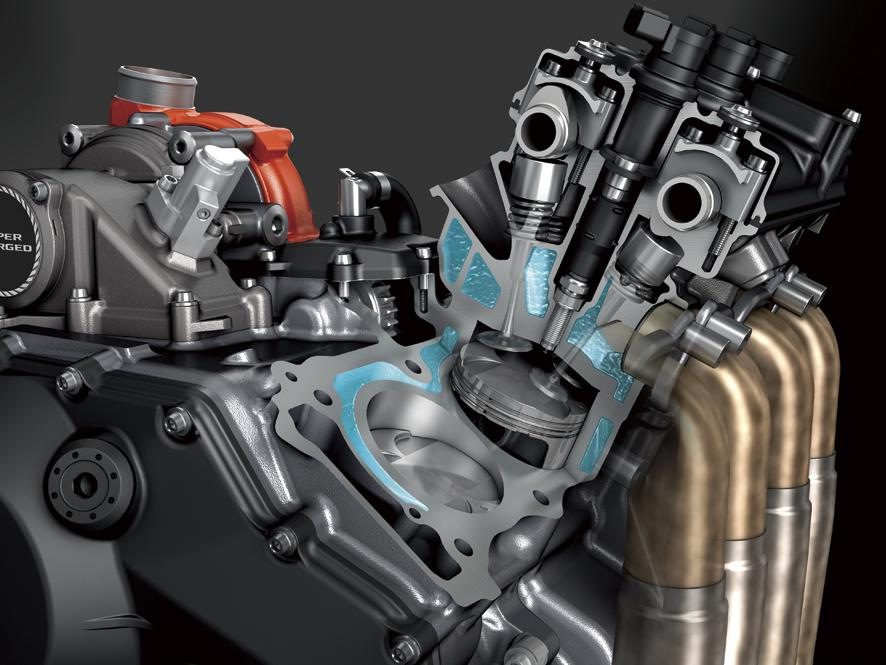

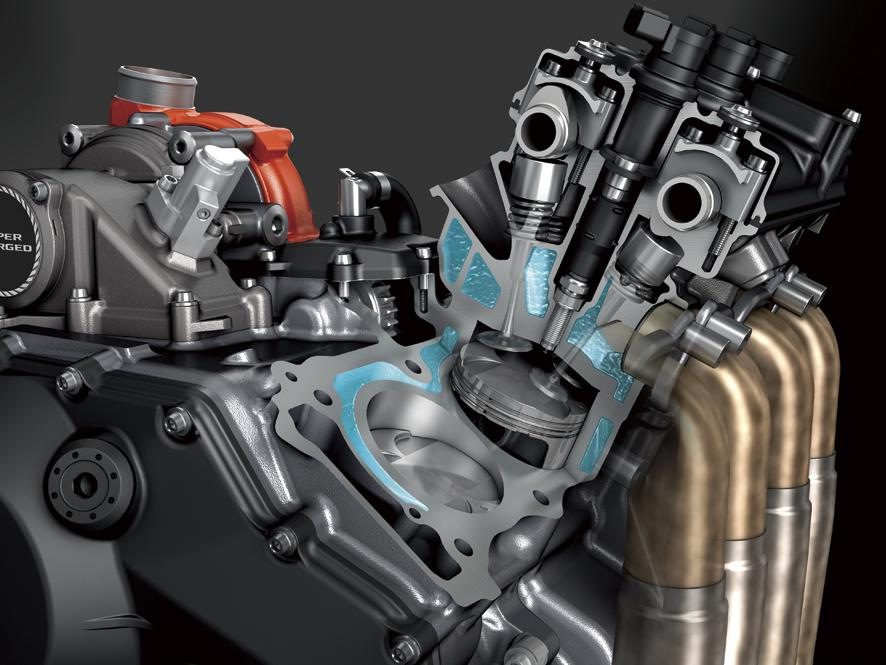

A number of considerations were given to the cylinder head design to ensure the cooling performance needed for the supercharged engine. The large coolant passageways result in the ideal cooling for the combustion chamber.

A number of considerations were given to the cylinder head design to ensure the cooling performance needed for the supercharged engine. The large coolant passageways result in the ideal cooling for the combustion chamber.

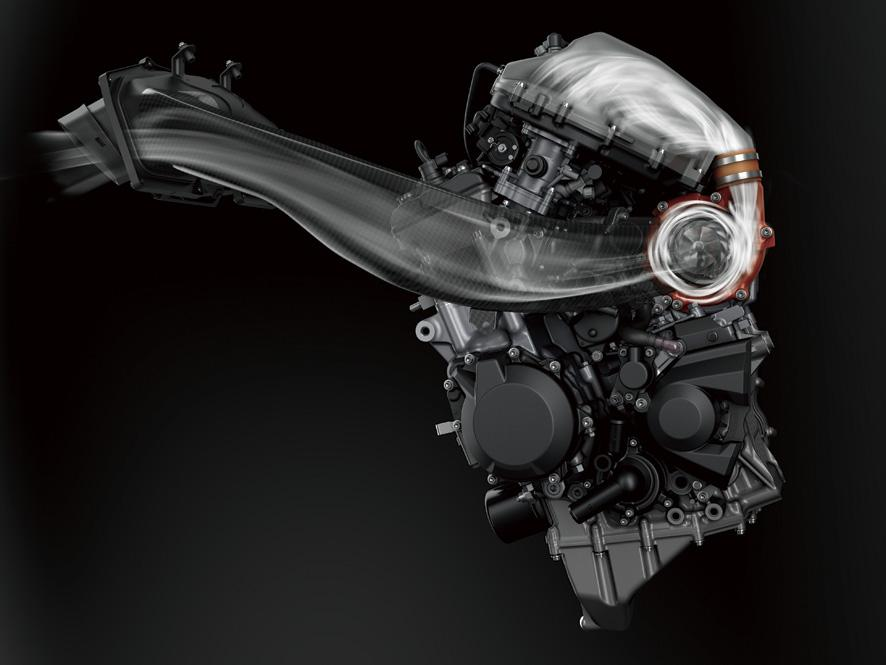

Air supplied to the supercharger enters via dual Ram Air intakes in the upper cowl. Their total frontal area is approximately 13,000 mm2—illustrating just how much air is needed to achieve the over 300 PS output.

Air supplied to the supercharger enters via dual Ram Air intakes in the upper cowl. Their total frontal area is approximately 13,000 mm2—illustrating just how much air is needed to achieve the over 300 PS output.

Using a trellis frame construction offered an elegant, lightweight solution to meeting the performance requirements for the chassis.

Using a trellis frame construction offered an elegant, lightweight solution to meeting the performance requirements for the chassis.

In the interest of keeping the engine compact and simple, a single lubrication system provides cooling oil for the engine components, supercharger and transmission.

In the interest of keeping the engine compact and simple, a single lubrication system provides cooling oil for the engine components, supercharger and transmission.

Special permission was obtained to use the River Mark on the Ninja H2R. Usually, its use on a product is reserved for models of historical significance.

Special permission was obtained to use the River Mark on the Ninja H2R. Usually, its use on a product is reserved for models of historical significance.

New instrument features include bank angle display and max bank angle recording function (possible thanks to the addition of the Inertial Measurement Unit)

New instrument features include bank angle display and max bank angle recording function (possible thanks to the addition of the Inertial Measurement Unit)

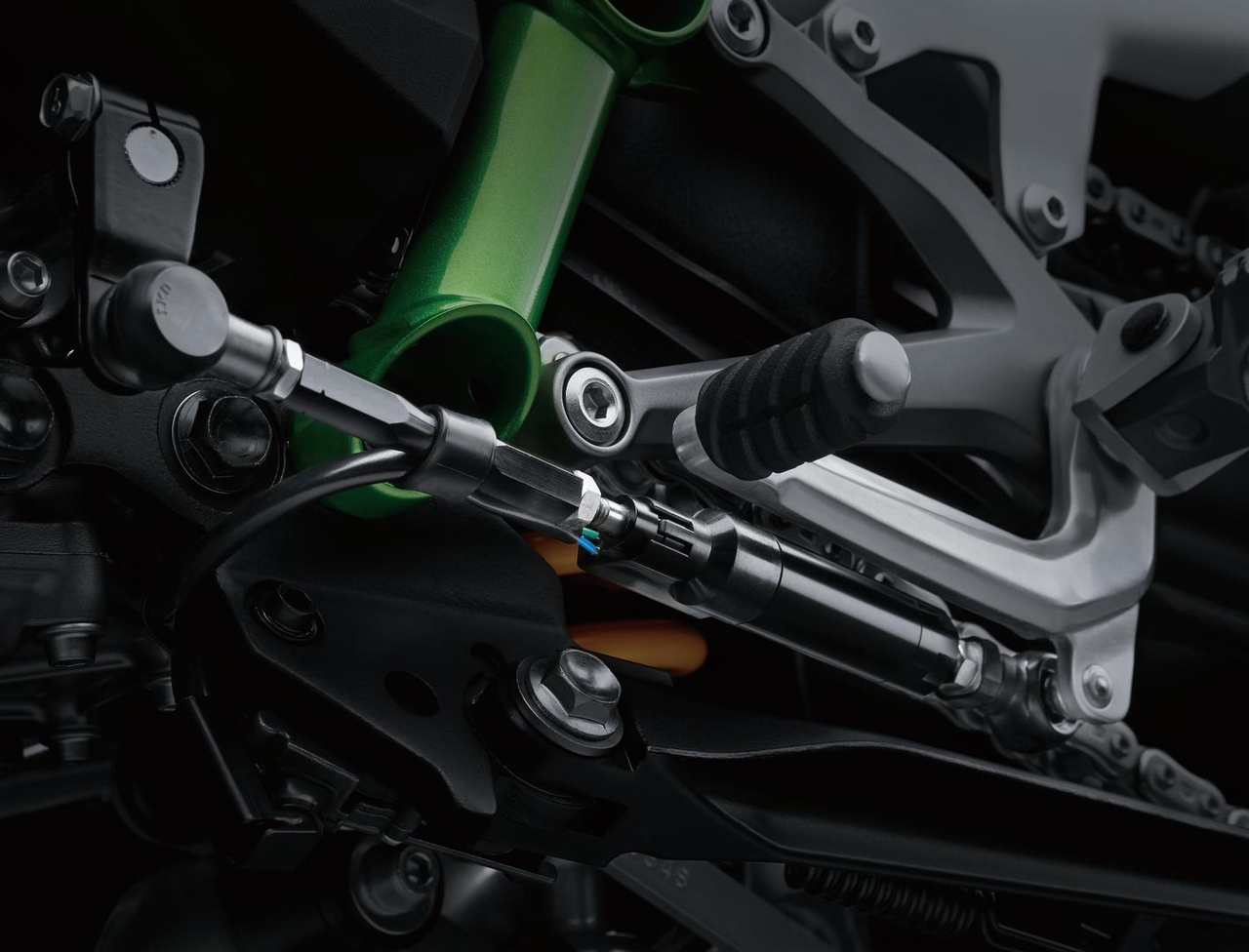

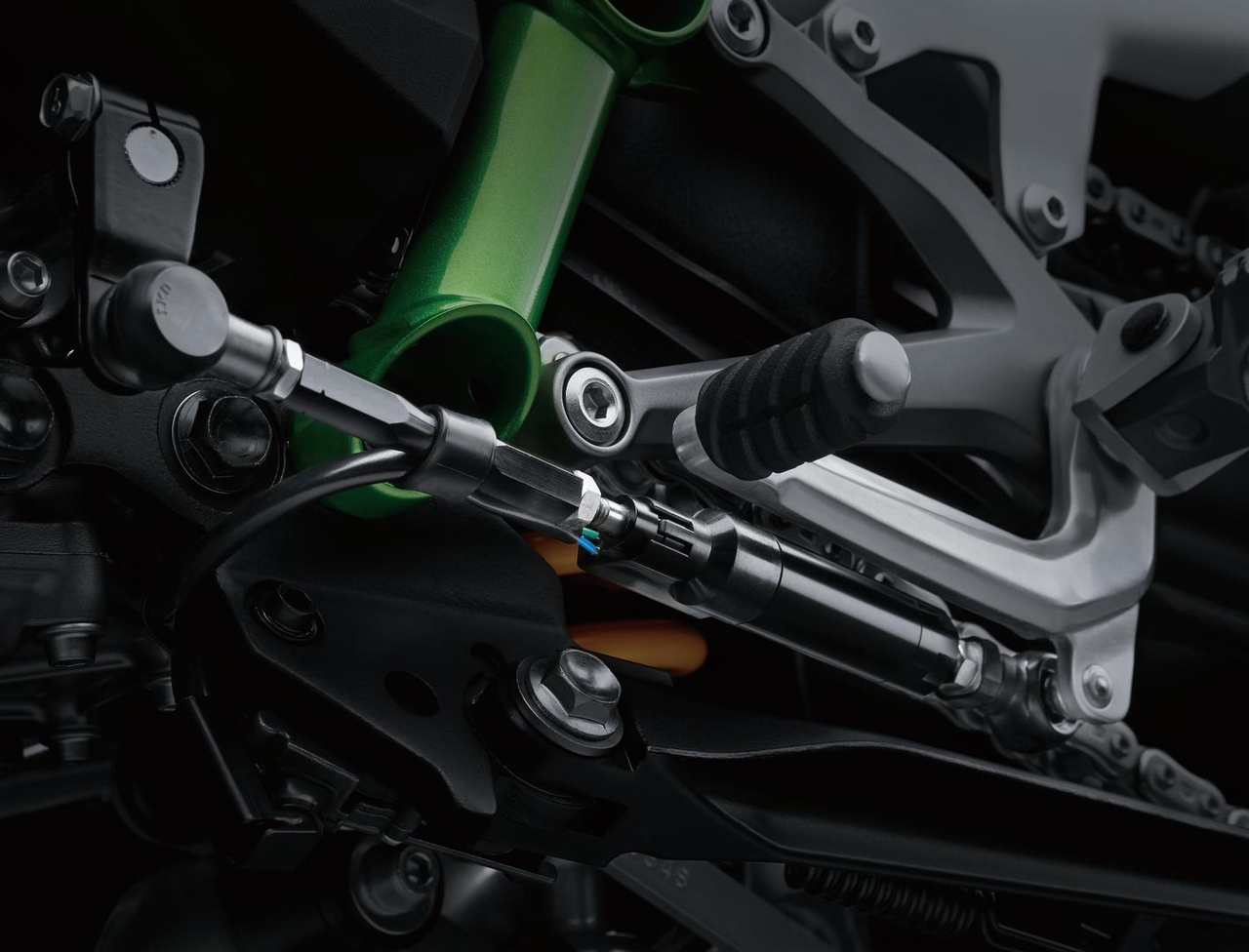

The Ninja H2R was the first Kawasaki motorcycle to be fit standard with a quick shifter. For 2017, the quick shifter also enables clutchless downshifts.

The Ninja H2R was the first Kawasaki motorcycle to be fit standard with a quick shifter. For 2017, the quick shifter also enables clutchless downshifts.

KCMF monitors engine and chassis parameters throughout the corner—from entry, through the apex, to corner exit—modulating brake force and engine power to facilitate smooth transition from acceleration to braking and back again, and to assist riders in tracing their intended line through the corner. On the Ninja H2, KCMF oversees the following systems: - KTRC (including traction, wheelie and sliding control) - KLCM - KIBS (including pitching and corner braking control) - Kawasaki Engine Brake Control

KCMF monitors engine and chassis parameters throughout the corner—from entry, through the apex, to corner exit—modulating brake force and engine power to facilitate smooth transition from acceleration to braking and back again, and to assist riders in tracing their intended line through the corner. On the Ninja H2, KCMF oversees the following systems: - KTRC (including traction, wheelie and sliding control) - KLCM - KIBS (including pitching and corner braking control) - Kawasaki Engine Brake Control

The riding position was designed for riding at ultra-high speed and circuit riding. To help support the rider during intense acceleration, hipsupporting pads flank the rear of the seat. The hip support is adjustable 15 mm backward to suit rider size.

The riding position was designed for riding at ultra-high speed and circuit riding. To help support the rider during intense acceleration, hipsupporting pads flank the rear of the seat. The hip support is adjustable 15 mm backward to suit rider size.

A pair of massive Ø 330 mm Brembo semi-floating discs with a thickness of t5.5 mm deliver superb braking force.

A pair of massive Ø 330 mm Brembo semi-floating discs with a thickness of t5.5 mm deliver superb braking force.

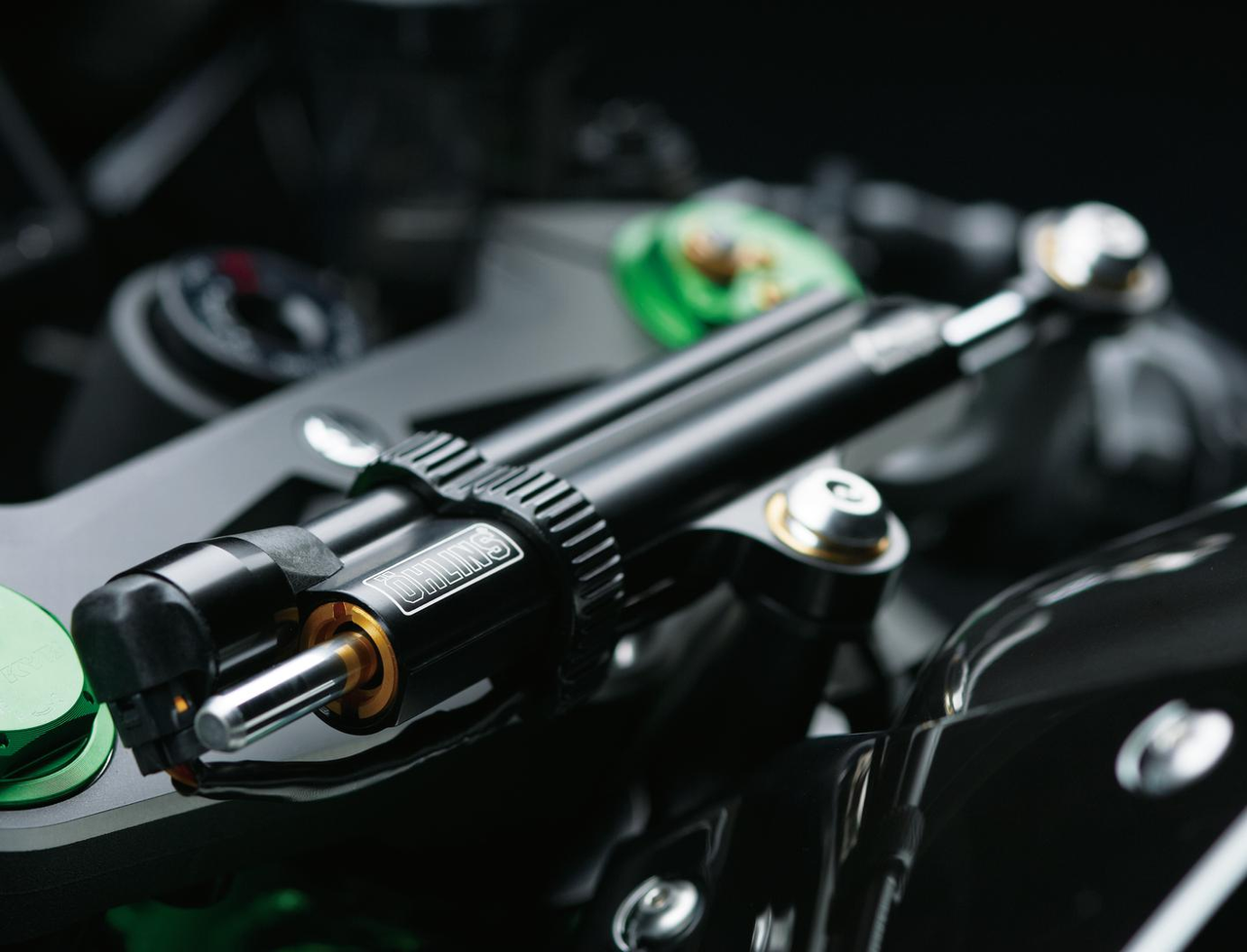

The addition of Öhlins’ highly acclaimed TTX shock offers numerous rider benefits: - Increased rear stability - excellent damping and increased riding comfort - Increased rear stability - Superb feedback from the road - More stability at speed.

The addition of Öhlins’ highly acclaimed TTX shock offers numerous rider benefits: - Increased rear stability - excellent damping and increased riding comfort - Increased rear stability - Superb feedback from the road - More stability at speed.

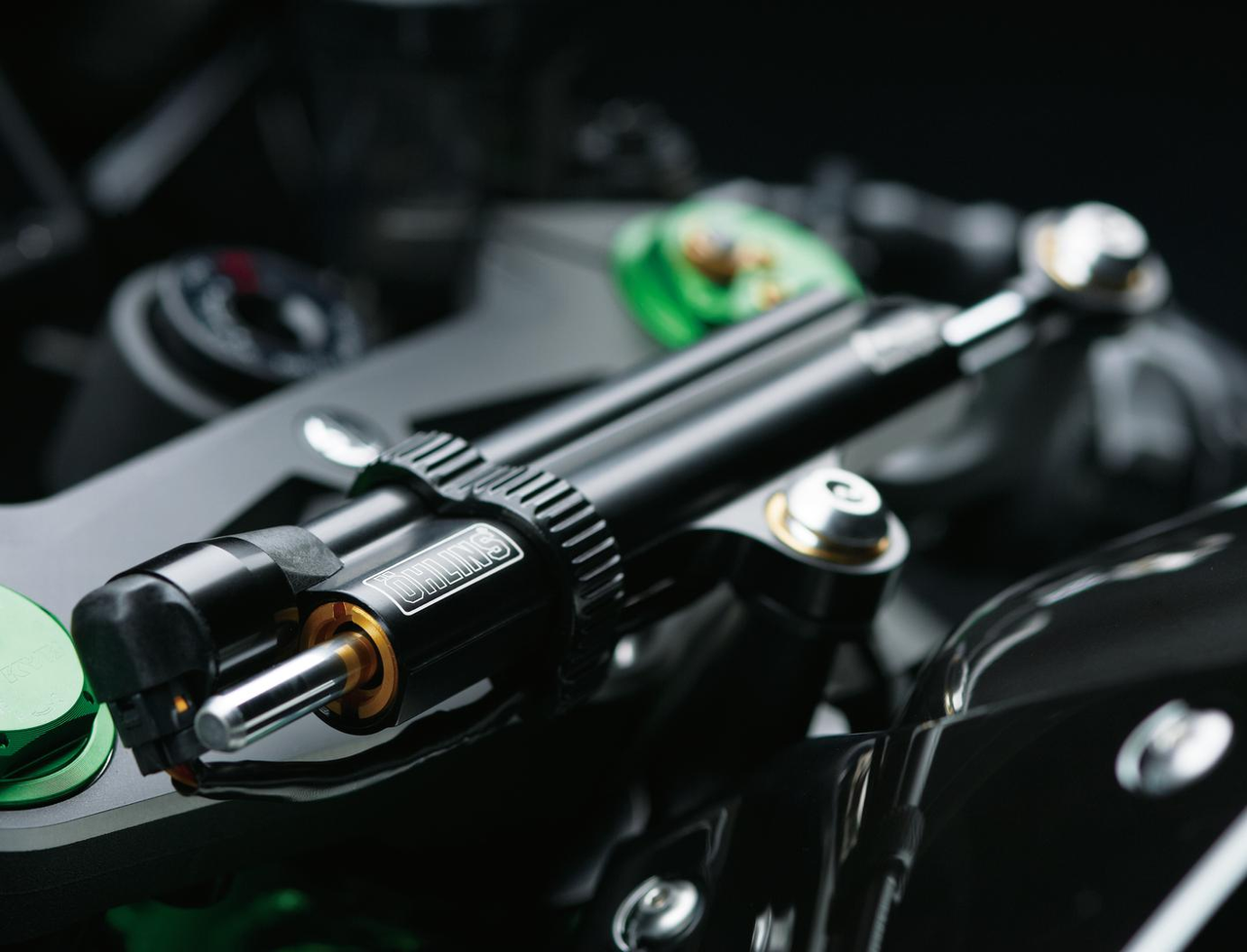

Kawasaki’s electronic steering damper was jointly developed with Öhlins, one of the most popular and respected manufacturers of steering dampers.

Kawasaki’s electronic steering damper was jointly developed with Öhlins, one of the most popular and respected manufacturers of steering dampers.

The use of Bosch’s compact IMU allows an additional layer of precision to be added to the already high-level KTRC, KLCM and KIBS.IMU enables inertia along 6 DOF (degrees of freedom) to be monitored. Acceleration along longitudinal, transverse and vertical axes, plus roll rate and pitch rate are measured.

The use of Bosch’s compact IMU allows an additional layer of precision to be added to the already high-level KTRC, KLCM and KIBS.IMU enables inertia along 6 DOF (degrees of freedom) to be monitored. Acceleration along longitudinal, transverse and vertical axes, plus roll rate and pitch rate are measured.

The supercharger used in the Ninja H2R was designed by Kawasaki motorcycle engine designers with assistance from other companies within the KHI Group, namely the Gas Turbine & Machinery Company, Aerospace Company, and Corporate Technology Division.

The supercharger used in the Ninja H2R was designed by Kawasaki motorcycle engine designers with assistance from other companies within the KHI Group, namely the Gas Turbine & Machinery Company, Aerospace Company, and Corporate Technology Division.

Despite it’s familiar In-Line Four configuration, the Ninja H2R power unit is loaded with technology developed specifically for this supercharged engine: some new, others with know-how from the Kawasaki Group.

Despite it’s familiar In-Line Four configuration, the Ninja H2R power unit is loaded with technology developed specifically for this supercharged engine: some new, others with know-how from the Kawasaki Group.

To facilitate smooth, quick shifting, a dog-ring type transmission was selected. This is the kind of transmission commonly found in MotoGP or Formula 1, and was developed with feedback from the Kawasaki Racing Team.

To facilitate smooth, quick shifting, a dog-ring type transmission was selected. This is the kind of transmission commonly found in MotoGP or Formula 1, and was developed with feedback from the Kawasaki Racing Team.

Kawasaki’s fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions

Kawasaki’s fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions

It is no accident that when viewed from the side, the Ninja H2R does not seem to have the aggressive forward-canted stance of most modern supersport models.

It is no accident that when viewed from the side, the Ninja H2R does not seem to have the aggressive forward-canted stance of most modern supersport models.

In place of mirrors, the Ninja H2R features CFRP wings mounted on the upper cowl.

In place of mirrors, the Ninja H2R features CFRP wings mounted on the upper cowl.

Full titanium exhaust system has a very simple design consisting of the header and collector pipes, a joint pipe, and a straightpipe megaphone-style silencer.

Full titanium exhaust system has a very simple design consisting of the header and collector pipes, a joint pipe, and a straightpipe megaphone-style silencer.

Having a single-sided swingarm allows the exhaust silencer to be mounted closer to the bike centreline, ensuring a high bank angle for sporty cornering.

Having a single-sided swingarm allows the exhaust silencer to be mounted closer to the bike centreline, ensuring a high bank angle for sporty cornering.

Kawasaki’s new Highly Durable paint features a special coat that allows scratches to repair themselves, enabling the paint to maintain its high-quality finish†. * Soft and hard segments in the coat work together like a chemical spring, creating a trampoline effect that absorbs impacts. † Notes: 1. In some cases, it takes about one week for recovery. 2. The paint will not recover in the case of scratches caused by a coin or key, or zip fasteners.

Kawasaki’s new Highly Durable paint features a special coat that allows scratches to repair themselves, enabling the paint to maintain its high-quality finish†. * Soft and hard segments in the coat work together like a chemical spring, creating a trampoline effect that absorbs impacts. † Notes: 1. In some cases, it takes about one week for recovery. 2. The paint will not recover in the case of scratches caused by a coin or key, or zip fasteners.

A high-quality hydraulic clutch offers less maintenance, ensuring the initial touch condition can be maintained. And with Brembo components, superb linearity and smooth actuation are also benefits.

A high-quality hydraulic clutch offers less maintenance, ensuring the initial touch condition can be maintained. And with Brembo components, superb linearity and smooth actuation are also benefits.

A number of considerations were given to the cylinder head design to ensure the cooling performance needed for the supercharged engine. The large coolant passageways result in the ideal cooling for the combustion chamber.

A number of considerations were given to the cylinder head design to ensure the cooling performance needed for the supercharged engine. The large coolant passageways result in the ideal cooling for the combustion chamber.

Air supplied to the supercharger enters via dual Ram Air intakes in the upper cowl. Their total frontal area is approximately 13,000 mm2—illustrating just how much air is needed to achieve the over 300 PS output.

Air supplied to the supercharger enters via dual Ram Air intakes in the upper cowl. Their total frontal area is approximately 13,000 mm2—illustrating just how much air is needed to achieve the over 300 PS output.

Using a trellis frame construction offered an elegant, lightweight solution to meeting the performance requirements for the chassis.

Using a trellis frame construction offered an elegant, lightweight solution to meeting the performance requirements for the chassis.

In the interest of keeping the engine compact and simple, a single lubrication system provides cooling oil for the engine components, supercharger and transmission.

In the interest of keeping the engine compact and simple, a single lubrication system provides cooling oil for the engine components, supercharger and transmission.

Special permission was obtained to use the River Mark on the Ninja H2R. Usually, its use on a product is reserved for models of historical significance.

Special permission was obtained to use the River Mark on the Ninja H2R. Usually, its use on a product is reserved for models of historical significance.

New instrument features include bank angle display and max bank angle recording function (possible thanks to the addition of the Inertial Measurement Unit)

New instrument features include bank angle display and max bank angle recording function (possible thanks to the addition of the Inertial Measurement Unit)

The Ninja H2R was the first Kawasaki motorcycle to be fit standard with a quick shifter. For 2017, the quick shifter also enables clutchless downshifts.

The Ninja H2R was the first Kawasaki motorcycle to be fit standard with a quick shifter. For 2017, the quick shifter also enables clutchless downshifts.

KCMF monitors engine and chassis parameters throughout the corner—from entry, through the apex, to corner exit—modulating brake force and engine power to facilitate smooth transition from acceleration to braking and back again, and to assist riders in tracing their intended line through the corner. On the Ninja H2, KCMF oversees the following systems: - KTRC (including traction, wheelie and sliding control) - KLCM - KIBS (including pitching and corner braking control) - Kawasaki Engine Brake Control

KCMF monitors engine and chassis parameters throughout the corner—from entry, through the apex, to corner exit—modulating brake force and engine power to facilitate smooth transition from acceleration to braking and back again, and to assist riders in tracing their intended line through the corner. On the Ninja H2, KCMF oversees the following systems: - KTRC (including traction, wheelie and sliding control) - KLCM - KIBS (including pitching and corner braking control) - Kawasaki Engine Brake Control

The riding position was designed for riding at ultra-high speed and circuit riding. To help support the rider during intense acceleration, hipsupporting pads flank the rear of the seat. The hip support is adjustable 15 mm backward to suit rider size.

The riding position was designed for riding at ultra-high speed and circuit riding. To help support the rider during intense acceleration, hipsupporting pads flank the rear of the seat. The hip support is adjustable 15 mm backward to suit rider size.

A pair of massive Ø 330 mm Brembo semi-floating discs with a thickness of t5.5 mm deliver superb braking force.

A pair of massive Ø 330 mm Brembo semi-floating discs with a thickness of t5.5 mm deliver superb braking force.

The addition of Öhlins’ highly acclaimed TTX shock offers numerous rider benefits: - Increased rear stability - excellent damping and increased riding comfort - Increased rear stability - Superb feedback from the road - More stability at speed.

The addition of Öhlins’ highly acclaimed TTX shock offers numerous rider benefits: - Increased rear stability - excellent damping and increased riding comfort - Increased rear stability - Superb feedback from the road - More stability at speed.

Kawasaki’s electronic steering damper was jointly developed with Öhlins, one of the most popular and respected manufacturers of steering dampers.

Kawasaki’s electronic steering damper was jointly developed with Öhlins, one of the most popular and respected manufacturers of steering dampers.

The use of Bosch’s compact IMU allows an additional layer of precision to be added to the already high-level KTRC, KLCM and KIBS.IMU enables inertia along 6 DOF (degrees of freedom) to be monitored. Acceleration along longitudinal, transverse and vertical axes, plus roll rate and pitch rate are measured.

The use of Bosch’s compact IMU allows an additional layer of precision to be added to the already high-level KTRC, KLCM and KIBS.IMU enables inertia along 6 DOF (degrees of freedom) to be monitored. Acceleration along longitudinal, transverse and vertical axes, plus roll rate and pitch rate are measured.

9-Mode KTRC (Kawasaki TRaction Control), Kawasaki’s most advanced traction control system, offers both enhanced sport riding performance and the peace of mind to negotiate slippery surfaces with confidence.

9-mode KTRC combines the best elements of Kawasaki’s earlier traction control systems. Riders can choose from three modes, each offering a progressively greater level of intrusion. Within each mode there are three rider-selectable levels, adding more or less intrusion (rider preferences for each mode are programmable for easy on-the-move selection from the left handle), for a total of nine possible settings. Riders may also elect to turn the system off.

The new KTRC system combines the logic and control of Kawasaki’s earlier traction control systems (S-KTRC, 1-mode KTRC) in each mode. Primary operation is similar to S-KTRC, which prioritises maximum forward acceleration using predictive-style intervention. But should excessive rear wheel speed be detected while operating in any mode, engine output is reduced to a level where grip can be regained, which provides rider reassurance by facilitating smooth riding on slippery surfaces.

Depending on the model, a Rain Mode is also included. This can be turned on and off independently of KTRC. Activating Rain Mode sets KTRC to Mode 3+, and also limits power output, torque and response. Similar to a Low Power setting, maximum engine output is reduced, and throttle response is milder.

The Economical Riding Indicator is a mark appearing on the instrument panel to indicate favourable fuel consumption, encouraging fuel efficient riding.

Using high-precision electronic control for engine management, Kawasaki models can achieve a high level of fuel efficiency. However, fuel consumption is greatly affected by throttle use, gear selection, and other elements under the rider's control. The Economical Riding Indicator is a function that indicates when current riding conditions are consuming a low amount of fuel. The system continuously monitors fuel consumption, regardless of vehicle speed, engine speed, throttle position and other riding conditions. When fuel consumption is low for a given speed (i.e. fuel efficiency is high), an "ECO" mark appears on the instrument panel's LCD screen. By riding so that the "ECO" mark remains on, fuel consumption can be reduced. While effective vehicle speed and engine speed may vary by model, paying attention to conditions that cause the "ECO" mark to appear can help riders improve their fuel efficiency – a handy way to increase cruising range. Further, keeping fuel consumption low also helps minimise negative impact on the environment.

ABS (Anti-lock Brake System) ensures stable braking performance by preventing wheel lock during braking.

Sudden over-application of the brakes, or braking on low-grip surfaces (surfaces with a low coefficient of friction) such as wet asphalt or manhole covers may cause a motorcycle's wheel(s) to lock up and slip. ABS was developed to prevent such incidents. Kawasaki ABS systems are controlled by high precision and highly reliable programming formulated based on thorough testing of numerous riding situations. By ensuring stable braking performance, they offer rider reassurance that contributes to greater riding enjoyment. And to meet the special requirements of certain riders, specialised ABS systems are also available. For example, KIBS (Kawasaki Intelligent anti-lock Brake System) is a high-precision brake system designed specifically for supersport models, enabling sport riding to be enjoyed by a wider range of riders. And by linking the front and rear brakes, K-ACT (Kawasaki Advanced Coactive-braking Technology) ABS provides the confidence to enjoy touring on heavyweight models. Kawasaki is continually working on the development of other advanced ABS systems.

Kawasaki’s original silver-mirror paint uses a layer of silver to create a highly reflective, glasslike metal appearance.

Kawasaki’s high-quality original paint has a highly reflective, glasslike metal appearance. Its debut on the 2015 Ninja H2 and Ninja H2R marked its first use on a mass-production vehicle in either the automotive or motorcycle industries.

In the shade the paint has the appearance of its base coat colour, but once in the sunlight its highly reflective surface takes on the appearance of the surrounding scenery. The stark difference in the way the paint appears in the light and the shade emphasises the sculpted shape of the bodywork on which it is applied.

The highly reflective surface is created by inducing a silver mirror reaction (a chemical reaction between a solution of silver ions and a reducing agent) that forms a layer of pure silver (Ag). This Ag layer is what creates the paint’s glasslike metal appearance. Compared to candy paints, which use aluminium flakes to generate a sparkling effect, the Ag layer appears as a uniform metallic surface.

In the shade the Ag layer is translucent, allowing the base coat colour to show through. This gives the paint a deep, three-dimensional quality.

While the multiple layers of paint on typical mass-production models are done by robot painters, for this silver-mirror paint each layer – from primer to clear coat – is carefully finished by the hands of Kawasaki craftsmen to ensure a flawless, lustrous surface.

Combined with Kawasaki’s proprietary dynamic modelling program, input from the IMU (Inertial Measurement Unit) enables even more precise chassis orientation awareness, the key to bringing Kawasaki’s electronics to the next level.

IMU means Enhanced Chassis Orientation Awareness. The strength of Kawasaki's cutting-edge electronics has always been the highly sophisticated programming that, using minimal hardware, gives the ECU an accurate real-time picture of what the chassis is doing. Kawasaki's proprietary dynamic modelling program makes skillful use of the magic formula tyre model as it examines changes in multiple parameters, enabling it to take into account changing road and tyre conditions. The addition of an IMU (Inertial Measurement Unit) enables inertia along 6 DOF (degrees of freedom) to be monitored. Acceleration along longitudinal, transverse and vertical axes, plus roll rate and pitch rate are measured. The yaw rate is calculated by the ECU. This additional feedback contributes to an even clearer real-time picture of chassis orientation, enabling even more precise management for control at the limit. With the addition of the IMU and the latest evolution of Kawasaki's advanced modelling software, Kawasaki's electronic engine and chassis management technology takes the step to the next level changing from setting-type and reaction-type systems to feedback-type systems to deliver even greater levels of riding excitement.

ERGO-FIT is an interface system that allows a wide range of riders to feel at one with their machine.

Proper fit is key for rider comfort and control. However, the ideal fit varies from rider to rider, depending on their physical dimensions and riding style. ERGO-FIT is an interface system designed to allow riders to find their ideal riding position. Various points of the chassis interface (the handlebar, footpegs and seat, etc) can be adjusted through a combination of interchangeable parts and parts with adjustable positions. This enables a wide range of riders to find a riding position that offers both comfort and control. Feeling at one with their machine, they will be able to experience how Kawasaki machines are fun and rewarding to ride. *Adjustable parts and their range of adjustability vary by model.

Electronic Throttle Valves allow the ECU to deliver the ideal amount of fuel and air to the engine.

Kawasaki's fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions. Electronic throttle valves also enable more precise control of electronic engine management systems like S-KTRC and KTRC, and allow the implementation of electronic systems like KLCM, Kawasaki Engine Brake Control, and Electronic Cruise Control.

KLCM (Kawasaki Launch Control Mode) optimises acceleration from a stop by electronically managing engine output to prevent wheelspin.

Designed to assist riders by optimising acceleration from a stop, KLCM electronically manages engine output to prevent wheelspin when moving off. Riders can choose from three modes, each offering a progressively greater level of intrusion. Each mode allows the rider to leave from a stop with the throttle held wide open. With the clutch lever pulled in and the system activated, engine speed is limited to a determined speed while the rider holds the throttle open. Once the rider releases the clutch lever to engage the clutch, engine speed is allowed to increase, but power is regulated to prevent wheelspin and help keep the front wheel on the ground. (In Mode 1, the least intrusive, the front wheel may lift a little.) The system disengages automatically at 150 km/h or when the rider shifts into 3rd gear.

KCMF (Kawasaki Cornering Management Function) monitors engine and chassis parameters throughout the corner.

KCMF monitors engine and chassis parameters throughout the corner from entry, through the apex, to corner exit modulating brake force and engine power to facilitate smooth transition from acceleration to braking and back again, and to assist riders in tracing their intended line through the corner. KCMF oversees the following systems (where available): KTRC (including traction, wheelie and sliding control), KIBS (including pitching control), Kawasaki Engine Brake Control

Kawasaki Engine Brake Control allows riders to set engine braking according to preference.

The Kawasaki Engine Brake Control system allows riders to select the amount of engine braking they prefer. When the system is activated, the engine braking effect is reduced, providing less interference when riding on the circuit.

Designed to help riders maximise their acceleration on the circuit by enabling clutchless upshifts with the throttle fully open, KQS detects that the shift lever has been actuated and sends a signal to the ECU to cut ignition so that the next gear can be engaged without having to use the clutch. On models that offer clutchless downshifts, during deceleration the system automatically controls engine speed so that the next lower gear can be selected without operating the clutch.

Designed completely in-house, the immense potential of the highly compact, highly efficient supercharged engine is a testament to the technology possessed by the KHI Group.

Drawing on the know-how and technology possessed by the KHI Group, Kawasaki’s supercharged engine delivers high engine output while maintaining a compact design. The key to achieving this incredible performance lies in the engine’s supercharger – a motorcycle-specific unit designed completely in-house with technology from Kawasaki’s Gas Turbine & Machinery Company, Aerospace Company and Corporate Technology Division.

One of the greatest benefits of designing the supercharger in-house and tailoring its design to match the engine’s characteristics was that engineers were able to achieve high-efficiency operation over a wide range of conditions – something that would not have been possible by simply dropping in or trying to adapt an aftermarket automotive supercharger.

The importance of high efficiency in a supercharger is that, as the air is compressed, power-robbing heat gain is minimal. And while many superchargers are able to offer high-efficiency operation in a very limited range of conditions, Kawasaki’s supercharger offers high efficiency over a wide range of pressure ratios and flow rates – meaning over a wide range of engine speeds and vehicle speeds. This wide range of efficient operation (similar to having a wide power band) easily translates to strong acceleration. The supercharger’s high efficiency and minimal heat gain also meant that an intercooler was unnecessary, greatly saving weight and space, and enabling the engine’s compact design.

KIBS (Kawasaki Intelligent anti-lock Brake System) is a high-precision brake system designed specifically for supersport models, offering highly efficient braking while maintaining natural feel.

Kawasaki developed KIBS to take into account the particular handling characteristics of supersport motorcycles, ensuring highly efficient braking with minimal intrusion during hard sport riding. It is the first mass-production brake system to link the ABS ECU (Electronic Control Unit) and engine ECU. In addition front and rear wheel speed, KIBS monitors front brake caliper hydraulic pressure, throttle position, engine speed, clutch actuation and gear position. This diverse information is analysed to determine the ideal front brake hydraulic pressure. Through precise control, the large drops in hydraulic pressure seen on standard ABS systems can be avoided. Additionally, the tendency on supersport models for the rear wheel to lift under heavy braking can be suppressed and rear brake controllability can be maintained when downshifting.

9-Mode KTRC (Kawasaki TRaction Control), Kawasaki’s most advanced traction control system, offers both enhanced sport riding performance and the peace of mind to negotiate slippery surfaces with confidence.

9-mode KTRC combines the best elements of Kawasaki’s earlier traction control systems. Riders can choose from three modes, each offering a progressively greater level of intrusion. Within each mode there are three rider-selectable levels, adding more or less intrusion (rider preferences for each mode are programmable for easy on-the-move selection from the left handle), for a total of nine possible settings. Riders may also elect to turn the system off.

The new KTRC system combines the logic and control of Kawasaki’s earlier traction control systems (S-KTRC, 1-mode KTRC) in each mode. Primary operation is similar to S-KTRC, which prioritises maximum forward acceleration using predictive-style intervention. But should excessive rear wheel speed be detected while operating in any mode, engine output is reduced to a level where grip can be regained, which provides rider reassurance by facilitating smooth riding on slippery surfaces.

Depending on the model, a Rain Mode is also included. This can be turned on and off independently of KTRC. Activating Rain Mode sets KTRC to Mode 3+, and also limits power output, torque and response. Similar to a Low Power setting, maximum engine output is reduced, and throttle response is milder.

The Economical Riding Indicator is a mark appearing on the instrument panel to indicate favourable fuel consumption, encouraging fuel efficient riding.

Using high-precision electronic control for engine management, Kawasaki models can achieve a high level of fuel efficiency. However, fuel consumption is greatly affected by throttle use, gear selection, and other elements under the rider's control. The Economical Riding Indicator is a function that indicates when current riding conditions are consuming a low amount of fuel. The system continuously monitors fuel consumption, regardless of vehicle speed, engine speed, throttle position and other riding conditions. When fuel consumption is low for a given speed (i.e. fuel efficiency is high), an "ECO" mark appears on the instrument panel's LCD screen. By riding so that the "ECO" mark remains on, fuel consumption can be reduced. While effective vehicle speed and engine speed may vary by model, paying attention to conditions that cause the "ECO" mark to appear can help riders improve their fuel efficiency – a handy way to increase cruising range. Further, keeping fuel consumption low also helps minimise negative impact on the environment.

ABS (Anti-lock Brake System) ensures stable braking performance by preventing wheel lock during braking.

Sudden over-application of the brakes, or braking on low-grip surfaces (surfaces with a low coefficient of friction) such as wet asphalt or manhole covers may cause a motorcycle's wheel(s) to lock up and slip. ABS was developed to prevent such incidents. Kawasaki ABS systems are controlled by high precision and highly reliable programming formulated based on thorough testing of numerous riding situations. By ensuring stable braking performance, they offer rider reassurance that contributes to greater riding enjoyment. And to meet the special requirements of certain riders, specialised ABS systems are also available. For example, KIBS (Kawasaki Intelligent anti-lock Brake System) is a high-precision brake system designed specifically for supersport models, enabling sport riding to be enjoyed by a wider range of riders. And by linking the front and rear brakes, K-ACT (Kawasaki Advanced Coactive-braking Technology) ABS provides the confidence to enjoy touring on heavyweight models. Kawasaki is continually working on the development of other advanced ABS systems.

Kawasaki’s original silver-mirror paint uses a layer of silver to create a highly reflective, glasslike metal appearance.

Kawasaki’s high-quality original paint has a highly reflective, glasslike metal appearance. Its debut on the 2015 Ninja H2 and Ninja H2R marked its first use on a mass-production vehicle in either the automotive or motorcycle industries.

In the shade the paint has the appearance of its base coat colour, but once in the sunlight its highly reflective surface takes on the appearance of the surrounding scenery. The stark difference in the way the paint appears in the light and the shade emphasises the sculpted shape of the bodywork on which it is applied.

The highly reflective surface is created by inducing a silver mirror reaction (a chemical reaction between a solution of silver ions and a reducing agent) that forms a layer of pure silver (Ag). This Ag layer is what creates the paint’s glasslike metal appearance. Compared to candy paints, which use aluminium flakes to generate a sparkling effect, the Ag layer appears as a uniform metallic surface.

In the shade the Ag layer is translucent, allowing the base coat colour to show through. This gives the paint a deep, three-dimensional quality.

While the multiple layers of paint on typical mass-production models are done by robot painters, for this silver-mirror paint each layer – from primer to clear coat – is carefully finished by the hands of Kawasaki craftsmen to ensure a flawless, lustrous surface.

Combined with Kawasaki’s proprietary dynamic modelling program, input from the IMU (Inertial Measurement Unit) enables even more precise chassis orientation awareness, the key to bringing Kawasaki’s electronics to the next level.

IMU means Enhanced Chassis Orientation Awareness. The strength of Kawasaki's cutting-edge electronics has always been the highly sophisticated programming that, using minimal hardware, gives the ECU an accurate real-time picture of what the chassis is doing. Kawasaki's proprietary dynamic modelling program makes skillful use of the magic formula tyre model as it examines changes in multiple parameters, enabling it to take into account changing road and tyre conditions. The addition of an IMU (Inertial Measurement Unit) enables inertia along 6 DOF (degrees of freedom) to be monitored. Acceleration along longitudinal, transverse and vertical axes, plus roll rate and pitch rate are measured. The yaw rate is calculated by the ECU. This additional feedback contributes to an even clearer real-time picture of chassis orientation, enabling even more precise management for control at the limit. With the addition of the IMU and the latest evolution of Kawasaki's advanced modelling software, Kawasaki's electronic engine and chassis management technology takes the step to the next level changing from setting-type and reaction-type systems to feedback-type systems to deliver even greater levels of riding excitement.

ERGO-FIT is an interface system that allows a wide range of riders to feel at one with their machine.

Proper fit is key for rider comfort and control. However, the ideal fit varies from rider to rider, depending on their physical dimensions and riding style. ERGO-FIT is an interface system designed to allow riders to find their ideal riding position. Various points of the chassis interface (the handlebar, footpegs and seat, etc) can be adjusted through a combination of interchangeable parts and parts with adjustable positions. This enables a wide range of riders to find a riding position that offers both comfort and control. Feeling at one with their machine, they will be able to experience how Kawasaki machines are fun and rewarding to ride. *Adjustable parts and their range of adjustability vary by model.

Electronic Throttle Valves allow the ECU to deliver the ideal amount of fuel and air to the engine.

Kawasaki's fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions. Electronic throttle valves also enable more precise control of electronic engine management systems like S-KTRC and KTRC, and allow the implementation of electronic systems like KLCM, Kawasaki Engine Brake Control, and Electronic Cruise Control.

KLCM (Kawasaki Launch Control Mode) optimises acceleration from a stop by electronically managing engine output to prevent wheelspin.

Designed to assist riders by optimising acceleration from a stop, KLCM electronically manages engine output to prevent wheelspin when moving off. Riders can choose from three modes, each offering a progressively greater level of intrusion. Each mode allows the rider to leave from a stop with the throttle held wide open. With the clutch lever pulled in and the system activated, engine speed is limited to a determined speed while the rider holds the throttle open. Once the rider releases the clutch lever to engage the clutch, engine speed is allowed to increase, but power is regulated to prevent wheelspin and help keep the front wheel on the ground. (In Mode 1, the least intrusive, the front wheel may lift a little.) The system disengages automatically at 150 km/h or when the rider shifts into 3rd gear.

KCMF (Kawasaki Cornering Management Function) monitors engine and chassis parameters throughout the corner.

KCMF monitors engine and chassis parameters throughout the corner from entry, through the apex, to corner exit modulating brake force and engine power to facilitate smooth transition from acceleration to braking and back again, and to assist riders in tracing their intended line through the corner. KCMF oversees the following systems (where available): KTRC (including traction, wheelie and sliding control), KIBS (including pitching control), Kawasaki Engine Brake Control

Kawasaki Engine Brake Control allows riders to set engine braking according to preference.

The Kawasaki Engine Brake Control system allows riders to select the amount of engine braking they prefer. When the system is activated, the engine braking effect is reduced, providing less interference when riding on the circuit.

Designed to help riders maximise their acceleration on the circuit by enabling clutchless upshifts with the throttle fully open, KQS detects that the shift lever has been actuated and sends a signal to the ECU to cut ignition so that the next gear can be engaged without having to use the clutch. On models that offer clutchless downshifts, during deceleration the system automatically controls engine speed so that the next lower gear can be selected without operating the clutch.

Designed completely in-house, the immense potential of the highly compact, highly efficient supercharged engine is a testament to the technology possessed by the KHI Group.

Drawing on the know-how and technology possessed by the KHI Group, Kawasaki’s supercharged engine delivers high engine output while maintaining a compact design. The key to achieving this incredible performance lies in the engine’s supercharger – a motorcycle-specific unit designed completely in-house with technology from Kawasaki’s Gas Turbine & Machinery Company, Aerospace Company and Corporate Technology Division.

One of the greatest benefits of designing the supercharger in-house and tailoring its design to match the engine’s characteristics was that engineers were able to achieve high-efficiency operation over a wide range of conditions – something that would not have been possible by simply dropping in or trying to adapt an aftermarket automotive supercharger.

The importance of high efficiency in a supercharger is that, as the air is compressed, power-robbing heat gain is minimal. And while many superchargers are able to offer high-efficiency operation in a very limited range of conditions, Kawasaki’s supercharger offers high efficiency over a wide range of pressure ratios and flow rates – meaning over a wide range of engine speeds and vehicle speeds. This wide range of efficient operation (similar to having a wide power band) easily translates to strong acceleration. The supercharger’s high efficiency and minimal heat gain also meant that an intercooler was unnecessary, greatly saving weight and space, and enabling the engine’s compact design.

KIBS (Kawasaki Intelligent anti-lock Brake System) is a high-precision brake system designed specifically for supersport models, offering highly efficient braking while maintaining natural feel.

Kawasaki developed KIBS to take into account the particular handling characteristics of supersport motorcycles, ensuring highly efficient braking with minimal intrusion during hard sport riding. It is the first mass-production brake system to link the ABS ECU (Electronic Control Unit) and engine ECU. In addition front and rear wheel speed, KIBS monitors front brake caliper hydraulic pressure, throttle position, engine speed, clutch actuation and gear position. This diverse information is analysed to determine the ideal front brake hydraulic pressure. Through precise control, the large drops in hydraulic pressure seen on standard ABS systems can be avoided. Additionally, the tendency on supersport models for the rear wheel to lift under heavy braking can be suppressed and rear brake controllability can be maintained when downshifting.

| Engine type | Liquid-cooled, 4-stroke, in-line four with Supercharger |

|---|---|

| Compression ratio | 8.3:1 |

| Valve system | DOHC, 16 valves |

| Bore x stroke | 76.0 x 55.0 mm |

| Displacement | 998 cm³ |

| Fuel system | Fuel injection with dual injection: 50 mm x 4 |

| Lubrication | Forced lubrication, wet sump |

| Starting system | Electric |

| Ignition system | Digital |

| Maximum power | 228.0 kW {310 PS} / 14,000 rpm |

|---|---|

| Maximum power with RAM Air | 240,0 kW {326 PS} / 14.000 rpm |

| Maximum torque | 165.0 N•m {16.8 kgf•m} / 12,500 rpm |

| Transmission | 6-speed, return shift |

| Clutch | Wet, multi disc |

| Primary reduction ratio | 1.551 (76/49) |

| Gear ratios 1st | 3.188 (51/16) |

| Gear ratios 2nd | 2.526 (48/19) |

| Gear ratios 3rd | 2.045 (45/22) |

| Gear ratios 4th | 1.727 (38/22) |

| Gear ratios 5th | 1.524 (32/21) |

| Gear ratios 6th | 1.348 (31/23) |

| Final drive | Sealed chain |

| Final reduction ratio | 2.333 (42/18) |

| Frame type | Trellis, high-tensile steel |

|---|---|

| Trail | 108 mm |

| Wheel travel front | 120 mm |

| Wheel travel rear | 135 mm |

| Tyre, front | 120/600 R17 |

| Tyre, rear | 190/650 R17 |

| L x W x H | 2,070 x 850 x 1,160 mm |

| Steering angle L/R | 27° / 27° |

| Wheel base | 1,450 mm |

| Ground clearance | 130 mm |

| Fuel capacity | 17.0 litres |

| Seat height | 830 mm |

| Curb mass | 216 kg |

| Front brake type | Dual semi-floating Brembo discs |

|---|---|

| Front brake diameter | Ø 330 mm |

| Front brake caliper type | Brembo radial-mount, Stylema monobloc, opposed 4-piston |

| Rear brake type | Single disc |

| Rear brake diameter | Ø 250 mm |

| Rear brake caliper type | Brembo, opposed dual-piston |

| Front suspension type | Inverted fork with compression and rebound damping, spring preload adjustability, and top-out springs |

| Front suspension diameter | Ø 43 mm |

| Rear suspension type | Uni-Trak, Öhlins TTX36 gas-charged shock with piggyback reservoir, compression and rebound damping, spring preload adjustability, and top-out spring |

Inpage Navigation Section: Accessories

Akrapovic lightweight titanium/carbon full racing exhaust system with pre muffler. New style hexagonal carbon muffler. Boss with double plug for fitment of optional oxygen sensor (2 diameters). Carbon mounting bracket. Sound level is 104 dB without dB killer and 98 dB with dB killer installed that makes it suitable for almost all racetracks.

Read MoreSpecial single-sided rear swingarm stand made specially for the Ninja H2 models.

Made from strong Anti-tear Honeycomb ripstop fabric. Heat resistance till 120 degrees Celcius. Subtle branding.

100% Polyester. With multi usable (back)packing string bag.

Fits: